Rod Cold-forged suspension rod

Product Introduction

Steel is a material of a certain shape, size, and performance made from steel ingots, billets, or steel through pressure processing. Most steel processing is carried out through pressure processing, causing plastic deformation of the processed steel (billets, ingots, etc.). According to the different processing temperatures of steel, it can be divided into two types: cold processing and hot processing.

Through precise manufacturing and reliable performance, cold-forged suspension rods provide sturdy support and long-term stability for your equipment, making them an ideal choice for improving equipment efficiency and reliability.

Classification:

OUTER PIPE

- Product Introduction

-

Cold-forged suspension rods are precision-manufactured using advanced cold forging technology and are widely used in suspension systems for automobiles, construction machinery, and other heavy equipment. By forming the metal at room temperature, they not only possess exceptional strength and toughness, but also ensure dimensional accuracy, meeting the stringent demands of high-intensity, high-load operating environments.

Key Features:

1. High Strength and Durability

The cold forging process creates a denser and more uniform metal structure for the suspension rod, resulting in higher compressive and tensile strength. This allows the rod to effectively withstand the impact forces generated by vehicles or machinery under high load conditions, extending its service life.

2. Precision Dimensional Control

Cold forging technology ensures precise and consistent suspension rod dimensions and shape, reducing post-processing errors, providing greater assembly accuracy and stability, and ensuring reliability in high-intensity operating environments.

3. Excellent Shock Absorption

The suspension rod is designed to absorb vibration and impact during vehicle or equipment operation, reducing vibration transmission, improving ride comfort and equipment stability, and minimizing damage caused by vibration. Applications:Cold-forged suspension rods are widely used in a variety of industries, including light and heavy-duty vehicles, construction machinery, construction equipment, and mining machinery. They are particularly suitable for applications requiring heavy loads and high impact, such as road transportation, mining, and construction.

Through precise manufacturing and reliable performance, cold-forged suspension rods provide sturdy support and long-term stability for your equipment, making them an ideal choice for improving equipment efficiency and reliability.

Previous Page

Next Page

Rod Cold-forged suspension rod

Product Introduction

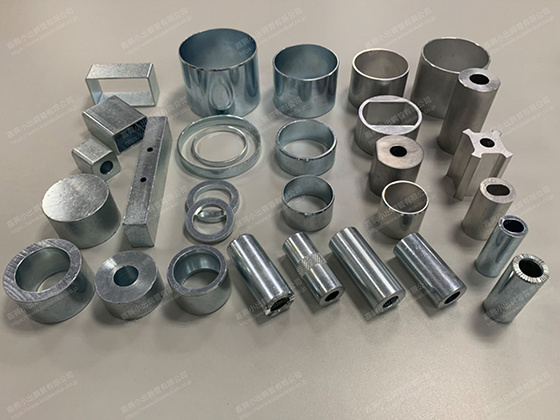

Our product is used as part of the shock-absorbing rubber to prevent various vibrations during car operation. The main product types are INNER/OUTER/MASS/SHAFT and other products used for anti vibration rubber. Not only for straight pipes, but also for various shapes and properties such as protrusions/flanges/two end flanges required by customers, technical evaluations have been conducted, and product development and production have been carried out within the company.

Through precise manufacturing and reliable performance, cold-forged suspension rods provide sturdy support and long-term stability for your equipment, making them an ideal choice for improving equipment efficiency and reliability.

Classification:

OUTER PIPE

- Product Introduction

-

Cold-forged suspension rods are precision-manufactured using advanced cold forging technology and are widely used in suspension systems for automobiles, construction machinery, and other heavy equipment. By forming the metal at room temperature, they not only possess exceptional strength and toughness, but also ensure dimensional accuracy, meeting the stringent demands of high-intensity, high-load operating environments.

Key Features:

1. High Strength and Durability

The cold forging process creates a denser and more uniform metal structure for the suspension rod, resulting in higher compressive and tensile strength. This allows the rod to effectively withstand the impact forces generated by vehicles or machinery under high load conditions, extending its service life.

2. Precision Dimensional Control

Cold forging technology ensures precise and consistent suspension rod dimensions and shape, reducing post-processing errors, providing greater assembly accuracy and stability, and ensuring reliability in high-intensity operating environments.

3. Excellent Shock Absorption

The suspension rod is designed to absorb vibration and impact during vehicle or equipment operation, reducing vibration transmission, improving ride comfort and equipment stability, and minimizing damage caused by vibration. Applications:Cold-forged suspension rods are widely used in a variety of industries, including light and heavy-duty vehicles, construction machinery, construction equipment, and mining machinery. They are particularly suitable for applications requiring heavy loads and high impact, such as road transportation, mining, and construction.

Through precise manufacturing and reliable performance, cold-forged suspension rods provide sturdy support and long-term stability for your equipment, making them an ideal choice for improving equipment efficiency and reliability.

Previous Page

Next Page

Contact Now

If you are interested in our products, please leave an email, we will contact you as soon as possible. Thank you.

Related Products