Precision Cold-Forged Shaft(Bar)

Product Introduction

Steel is a material of a certain shape, size, and performance made from steel ingots, billets, or steel through pressure processing. Most steel processing is carried out through pressure processing, causing plastic deformation of the processed steel (billets, ingots, etc.). According to the different processing temperatures of steel, it can be divided into two types: cold processing and hot processing.

Precision Cold-Forged Shaft strictly controls key dimensional parameters during the manufacturing process to ensure that each product has excellent coaxiality, surface finish, and shape and position accuracy.

Classification:

OUTER PIPE

- Product Introduction

-

Precision Cold-Forged Shaft is a high-strength, high-precision shaft component specially used in the automotive field. It is manufactured using advanced cold forging technology and is an indispensable structural core in key parts such as engines, gearboxes, and transmission systems. Through high-pressure plastic forming technology under room temperature conditions, cold forging not only avoids the problem of material grain coarsening caused by traditional hot processing, but also significantly improves the density and uniformity of metal structure, thus giving the product excellent mechanical strength and fatigue resistance. With its extremely high dimensional stability and excellent processing consistency, it is widely used in various types of automobiles and core components, providing a solid guarantee for the power output and stable operation of the vehicle.

Precision Cold-Forged Shaft strictly controls key dimensional parameters during the manufacturing process to ensure that each product has excellent coaxiality, surface finish, and shape and position accuracy. After cold forging, it usually only requires a very small amount of subsequent processing to meet the quality standards of the assembly level, greatly improving production efficiency and reducing processing costs. The shaft can be flexibly customized in length, diameter, end structure, keyway or spline form according to the needs of automobile manufacturers or first-tier suppliers, and is widely used in various functional parts such as drive shafts, steering shafts, output shafts, gear shafts, etc. The product can be further combined with various surface treatment processes such as heat treatment, electroplating, phosphating, etc. to effectively improve its corrosion resistance, wear resistance and long-term stability.

In harsh environments such as high-speed operation of automobiles, high-load impact and long-term fatigue cycles, Precision Cold-Forged Shaft shows excellent stability and durability. Its high-strength metal structure can effectively prevent the bending, breaking and deformation of the shaft during high torque transmission, greatly improving the service life and operational reliability of the automobile system. At the same time, the advantages of high material utilization, green environmental protection, and high forming efficiency of the cold forging process also meet the current technical trend requirements of the automobile manufacturing industry for lightweight and sustainable development. As one of the important basic parts for professional automobile parts manufacturing, Automotive steel shaft not only ensures the stable output of vehicle performance, but also helps the automobile industry move towards a new stage of higher-end and more efficient intelligent manufacturing.

Previous Page

Next Page

Precision Cold-Forged Shaft(Bar)

Product Introduction

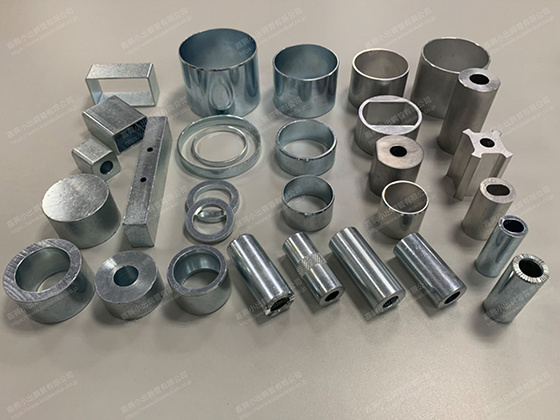

Our product is used as part of the shock-absorbing rubber to prevent various vibrations during car operation. The main product types are INNER/OUTER/MASS/SHAFT and other products used for anti vibration rubber. Not only for straight pipes, but also for various shapes and properties such as protrusions/flanges/two end flanges required by customers, technical evaluations have been conducted, and product development and production have been carried out within the company.

Precision Cold-Forged Shaft strictly controls key dimensional parameters during the manufacturing process to ensure that each product has excellent coaxiality, surface finish, and shape and position accuracy.

Classification:

OUTER PIPE

- Product Introduction

-

Precision Cold-Forged Shaft is a high-strength, high-precision shaft component specially used in the automotive field. It is manufactured using advanced cold forging technology and is an indispensable structural core in key parts such as engines, gearboxes, and transmission systems. Through high-pressure plastic forming technology under room temperature conditions, cold forging not only avoids the problem of material grain coarsening caused by traditional hot processing, but also significantly improves the density and uniformity of metal structure, thus giving the product excellent mechanical strength and fatigue resistance. With its extremely high dimensional stability and excellent processing consistency, it is widely used in various types of automobiles and core components, providing a solid guarantee for the power output and stable operation of the vehicle.

Precision Cold-Forged Shaft strictly controls key dimensional parameters during the manufacturing process to ensure that each product has excellent coaxiality, surface finish, and shape and position accuracy. After cold forging, it usually only requires a very small amount of subsequent processing to meet the quality standards of the assembly level, greatly improving production efficiency and reducing processing costs. The shaft can be flexibly customized in length, diameter, end structure, keyway or spline form according to the needs of automobile manufacturers or first-tier suppliers, and is widely used in various functional parts such as drive shafts, steering shafts, output shafts, gear shafts, etc. The product can be further combined with various surface treatment processes such as heat treatment, electroplating, phosphating, etc. to effectively improve its corrosion resistance, wear resistance and long-term stability.

In harsh environments such as high-speed operation of automobiles, high-load impact and long-term fatigue cycles, Precision Cold-Forged Shaft shows excellent stability and durability. Its high-strength metal structure can effectively prevent the bending, breaking and deformation of the shaft during high torque transmission, greatly improving the service life and operational reliability of the automobile system. At the same time, the advantages of high material utilization, green environmental protection, and high forming efficiency of the cold forging process also meet the current technical trend requirements of the automobile manufacturing industry for lightweight and sustainable development. As one of the important basic parts for professional automobile parts manufacturing, Automotive steel shaft not only ensures the stable output of vehicle performance, but also helps the automobile industry move towards a new stage of higher-end and more efficient intelligent manufacturing.

Previous Page

Next Page

Contact Now

If you are interested in our products, please leave an email, we will contact you as soon as possible. Thank you.

Related Products